Production: craftsmanship and innovation

We want to be transparent because we are proud of the way we make our garments. We believe that using innovative technologies and natural processes we can create sustainable and high quality clothing.

Designed to innovate

As it is now clear, the activity of the fashion industry causes numerous damages to the environment and living beings: contamination of water and soil, disfigurement of non-renewable resources, damage to human health as well as lack of safety in the workplace, exploitation of animals and people and racial and cultural discrimination.

As a response to these problems that we can no longer ignore, we have chosen: a raw material that does not spoil the environment; a production that does not pollute and respects the rights of human beings; a process that protects the artisan culture of our country; a dyeing method that is neither toxic to the environment nor to your skin.

Designed to last

Thuja garments are designed to last a long time and maintain quality over time. Production is limited in order to counteract overproduction, excessive consumption and waste, or the dynamics of Fast Fashion: Thuja offers garments that last a lifetime, it does not follow seasonal collections, but focuses entirely on the creation of products of high quality with minimum environmental impact. Thuja rejects the traditional fashion cycle that promotes discounts and excessive consumption.

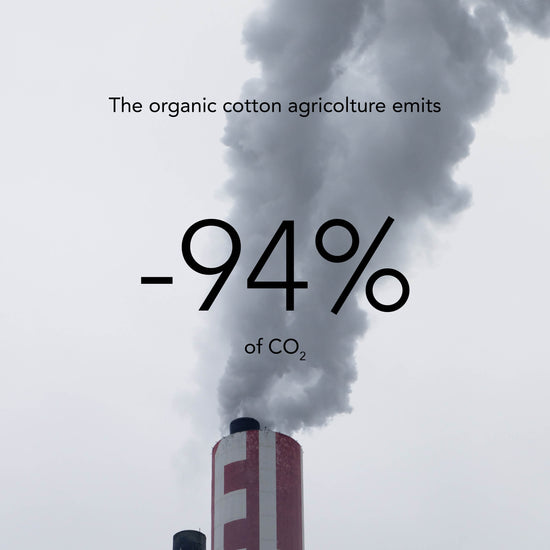

Sustainability is a means of growth and we all know that there are no shortcuts in creating high quality and long lasting products. We closely monitor our manufacturers to ensure that all of our products are made to our rigorous sustainability standards and work with Italian manufacturers to reduce distances and CO2 emissions.

The production process

The raw material

INDIA

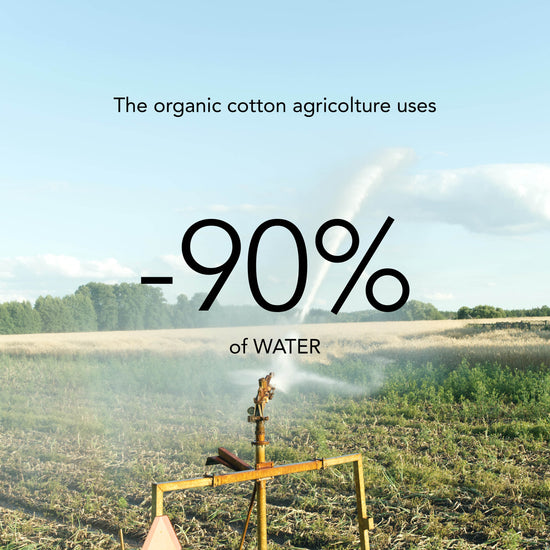

Thuja garments are made from 100% organic cotton. We use fibers from non-food crops that are grown responsibly according to organic production standards that do not include synthetic pesticides or herbicides and GMOs.

The cotton grown in this way not only helps reduce soil and water pollution, but is also good for the skin. The cultivation of our organic fibers is covered by the IFOAM international and national organic farming standard.

Spinning

Treviso, ITALY

To get to the fabric, the cotton fiber is first transformed into yarn. For cotton, ginning is the first stage of processing, during which the seeds are removed from the cotton balls. These are then inserted into a machine that obtains fiber segments a few centimeters long, which in turn are rolled up to form threads.

All stages of processing and production of the fabrics we use are covered by the GOTS Organic certification, which respects strict ecological and social criteria.

The weaving

Treviso, ITALY

All our fabrics are GOTS Organic certified.

The weaving phase sees the creation of the fabric starting from the yarn through a complex process carried out with the utmost care by expert craftsmen.

For our sweatshirts and trousers we have chosen an internal diagonal processing, which makes the fabric soft and gives a feeling of comfort and lightness; the t-shirts, on the other hand, have a very rules structure that makes them comfortable and perfect for every day.

The packaging

Treviso, ITALY

Once woven, cotton is cut and sewn by artisans in Treviso. Arrived at this stage, in fact, the garment is a set of pieces of fabric that must be joined together.

The various parts are sewn with the use of sewing machines, and for the details we proceed by hand with needle and thread. After dyeing, the labels in recycled material, produced in Mantua, and the Thuja logo are applied.

The tincture

Modena, ITALY

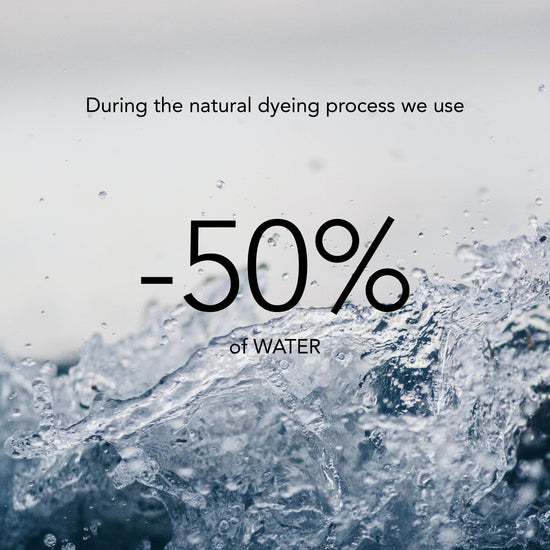

Thuja dyes are dyes derived from plants grown in vegetable gardens in the Mantua area and minerals and are fixed with alum and iron sulphate, auxiliaries of organic origin certified GOTS 6.0 and Zdhc 1.1.

Each plant gives specific properties to the fabric, making it hypoallergenic, antibacterial, resistant to sweating. The post-production water is not polluted and the non-toxic dyes and the absence of odorous chemicals make both the workplace and the environment safe.

The finishing

Mantua, ITALY

In the final phase, the garment is first rinsed, in order to remove any residues and make it clean, and then it is ironed. The tags are then applied, folded and placed in its own compostable packaging.

Finally, we deliver the package to the courier: we use logistics services with emissions compensation for all shipments, we use electric transport in the locations that have joined.

Scan the QR Code in the Maintenance label of your Thuja garment to access the digital production passport

Or find out in the "production" section of each product on our website

Our data

The colors of nature

-

Natural dyes come from renewable sources, such as plants and minerals, which can be replenished responsibly

-

Industrial dyeing has a high environmental footprint, as it requires a high volume of chemicals and water